Microbial contamination testing in biopharmaceutical manufacturing

The biopharmaceutical industry is working towards automating the entire manufacturing workflow (Pharma 4.0), where real-time data and artificial intelligence will maximize manufacturing efficiency.

To achieve Pharma 4.0, it is critical to have automated in-process microbial testing, yet no technology is currently meeting the industry’s needs.

This provides an exceptional opportunity for MantaBio and the MantaVision® System.

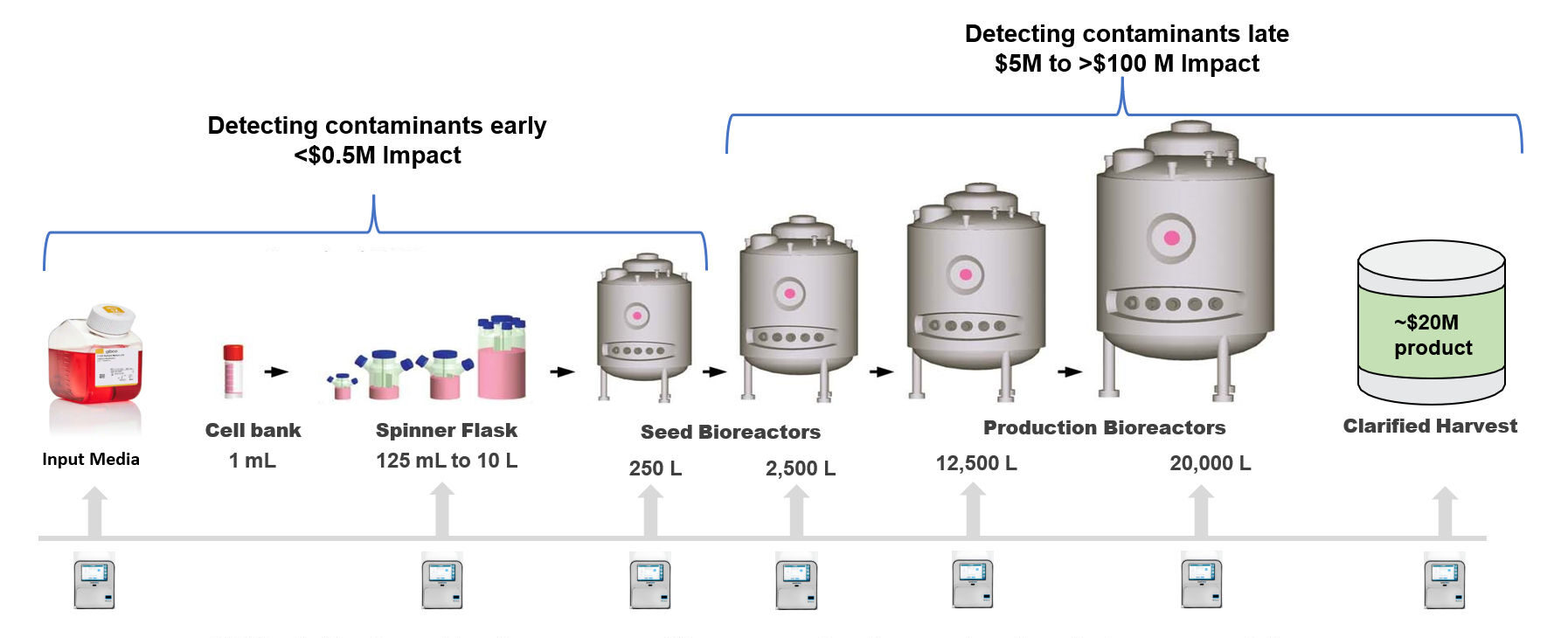

The biopharmaceutical manufacturing process has significant risks of microbial contamination. The inability to identify a contamination early in the process can result in:

- Loss of product

- Loss of manufacturing time

- Extensive cleaning

- Lost revenue

Larger Bioreactors = Increased Contamination Incident Risk and the Potential Cost of an Incident

For example, a leading global biopharmaceutical company was fined $175M by the FDA for releasing contaminated product and the impact to the company was likely $100’s of millions more.1

Every major manufacturer has to deal with contamination incidences, but since most are caught before product is released – notification of these incidences never make it into the public domain. Nonetheless, contaminations remain a significant and costly problem for the industry.

Two leading biopharmaceutical manufacturers purchased MantaBio’s MantaVision System and successfully completed feasibility studies. Following these studies, they expressed interest in a system specifically designed for the industry that meets its requirements.

Rapid Screening

Our MantaVision System is an automated, PCR system that allows users to test for numerous contaminants onsite, returning results in ~2 hours.

Learn more about the MantaVision System

Next Generation Biomanufacturing

Shifting towards the next era of biomanufacturing stands as a top priority for the industry, and in-process microbial testing will play a pivotal role.

Biopharma companies are steadily moving toward intensified, continuous, and automated production of biologics, often referred to as “biopharma 4.0”.

The 4.0 transformation relies on advanced instrumentation, including process analytical technology, or PAT, to achieve this objective.

4.0 PAT must enable testing at-line (requires sampling but enables faster turnaround time), on-line (connected to the process line), or in-line (fully integrated into the line). MantaBio’s MantaVision System is intended to first be used in near-line settings. As the technology matures, the goal is to move the technology to at-line environments.

A full industry shift will take a number of years, but forward-looking companies have a persistent interest in adopting advanced technology to enable this transformation.

While 4.0-capable analytical techniques are already being implemented to evaluate the properties of a drug itself, 4.0-compatible tools for microbial testing remain a bottleneck and present a compelling opportunity for MantaBio.

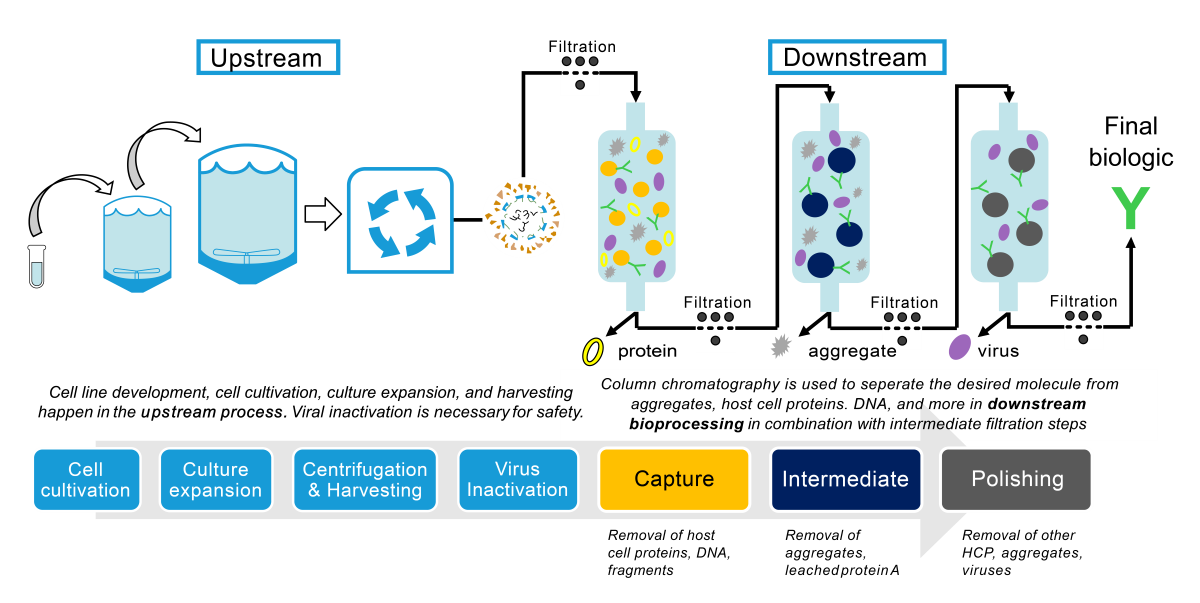

During biopharmaceutical manufacturing, routine microbial contamination screening is essential to ensure a safe product and to maintain manufacturing efficiency.

Within any large biopharmaceutical company, there are multiple departments beyond manufacturing that can benefit from MantaBio’s technology, including: R&D, Process Development, Analytical Development, Process Analytical Technologies, & QA/QC

Learn more about MantaVision